FLEXIBLE METAL HOSES

S.S. CORRUGATED FLEXIBLE HOSES

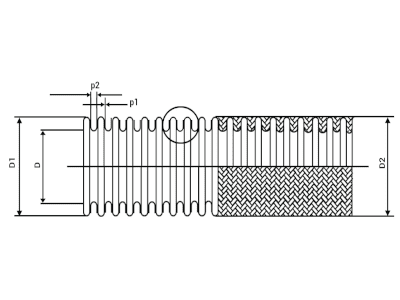

Structure

Annular corrugated flexible metal hoses can be produced from longitudinally welded tubes corrugated mechanically with or with out braiding

Standards

EN ISO 10380

Hose material

Stainless steel AISI 304, AISI 321 and AISI316L

Braiding material

Stainless steel AISI 304 and 316 L

Applications

In almost all industries like plastic processing, Cable manufacturing, Food, Pharma and Chemicalindustries etc.

End connections

Threaded ends welded connections Flanges as per customer specifications

Std Coils

DN6-25 -15m, 25m, 30m and 50m | DN32-50 -15m, 25m,30m and 50m | DN65-100 -25m

Temperature Range

-270℃ to +600℃

Technical Data

| NORMAL BORE | MINIMUM BEND RADIUS | WITHOUT BRAID | SINGLE BRAID | DOUBLE BRAID | ||||

|---|---|---|---|---|---|---|---|---|

| N.B. (mm) | Static (mm) | Flexing (mm) | Max - Working Pressure (kg/cm2) | Test Pressure (kg/cm2) | Max - Working Pressure (kg/cm2) | Test Pressure (kg/cm2) | Max - Working Pressure (kg/cm2) | Test Pressure (kg/cm2) |

| 6 | 25 | 100 | 4 | 6 | 100 | 150 | 160 | 240 |

| 10 | 40 | 150 | 4 | 6 | 90 | 135 | 144 | 16 |

| 12 | 50 | 200 | 3 | 4.5 | 80 | 120 | 128 | 192 |

| 16 | 50 | 200 | 3 | 4.5 | 70 | 105 | 112 | 168 |

| 20 | 70 | 200 | 2 | 3 | 64 | 96 | 102 | 153 |

| 25 | 90 | 200 | 2 | 3 | 50 | 75 | 80 | 120 |

| 32 | 110 | 250 | 1.5 | 2.3 | 40 | 60 | 64 | 96 |

| 40 | 130 | 250 | 1.5 | 2.3 | 30 | 45 | 48 | 72 |

| 50 | 175 | 350 | 1 | 1.5 | 23 | 42 | 44 | 66 |

| 65 | 200 | 410 | 1 | 1.5 | 24 | 36 | 38 | 57 |

| 80 | 205 | 450 | 1 | 1.5 | 18 | 27 | 28 | 42 |

| 100 | 230 | 560 | 0.8 | 1.2 | 16 | 24 | 26 | 39 |

| 125 | 280 | 660 | 0.6 | 0.9 | 12 | 18 | 20 | 30 |

| 150 | 320 | 815 | 0.6 | 0.9 | 10 | 15 | 16 | 20 |

| 200 | 435 | 1015 | 0.5 | 0.75 | 8 | 12 | 12 | 16 |